The essay focuses on prefabricated houses as a solution to the housing crisis. The prefab style is focused on Naoto Fukasawa product MUJI hut. Fukasawa is a Japanese industrial designer. Here MUJI hut is described as a concept and inspiration for prefabricated houses. The essay provides a solution for the housing problems and concludes housing needs.

The central body of the essay emphasizes how prefab houses can be used. The famous product like Muji-hut is analyzed and illustrated as a central part of the essay. The design can be evaluated through the ergonomics, cost, aesthetics, construction method/process, safety, and environmental impact. Hence it also serves as a solution for the housing crisis found around the world.

MUJI Hut, which is a prefabricated cabin, is explored here. The cabin is strongly reflected in human-centered design. Space is designed by taking inspiration from traditional Japanese techniques. The MUJI hut strongly emphasizes perceptive usability, simplicity, affordance and the interaction between the user and the product.

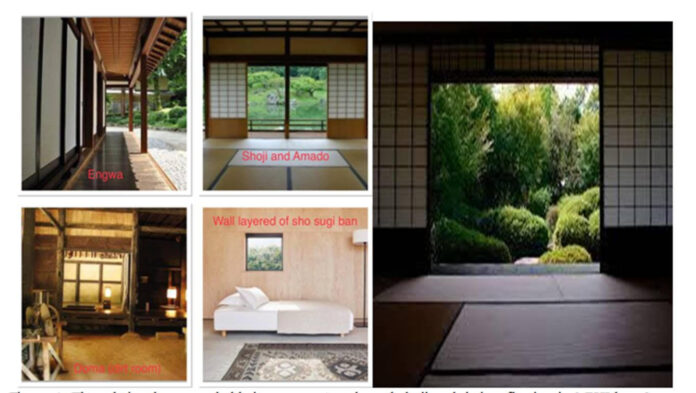

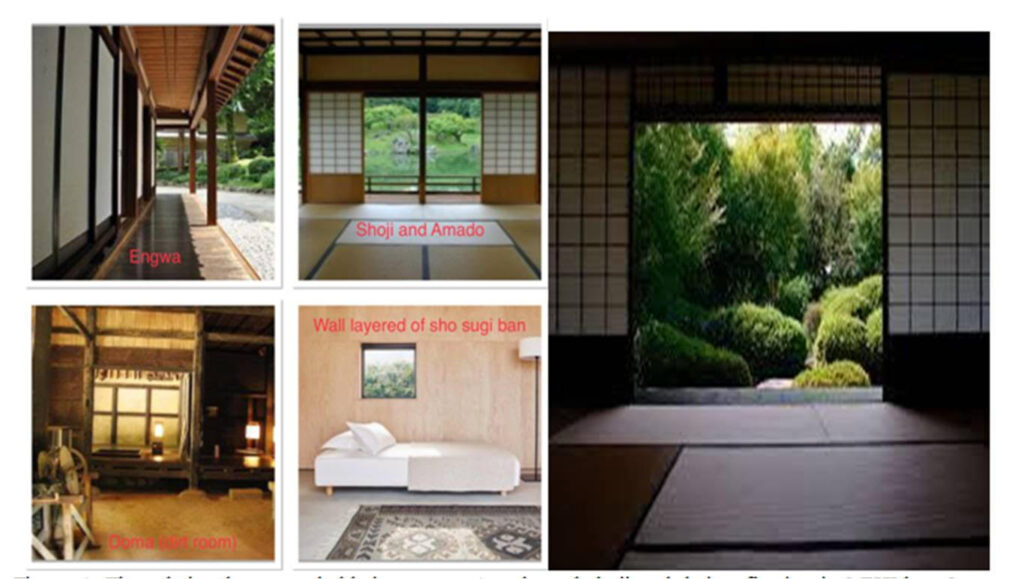

Figure 1. The beauty of design with nature balances the emptiness of the spaces. Source: Musi

The cabin shown in (fig. 1) is a single closet that quickly dissolves in the environment. The minimalist hut is small, mobile, robust and temporary. It is easier to work remotely due to advanced technology. This leads to an option between permanent and temporary residence. Basic requisites and furniture are added which make it portable. It can be placed wherever you want if it fulfills your requirements.

Product Analysis

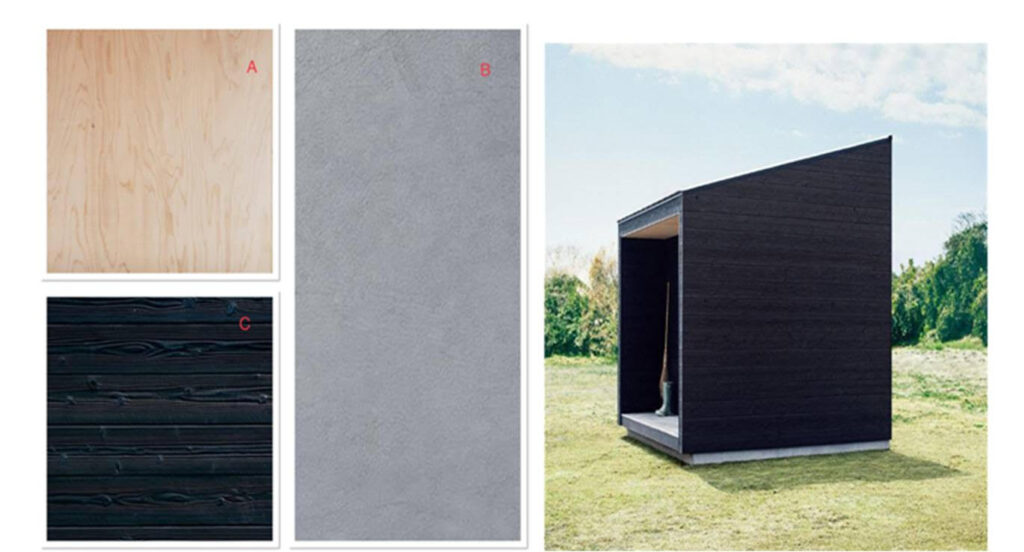

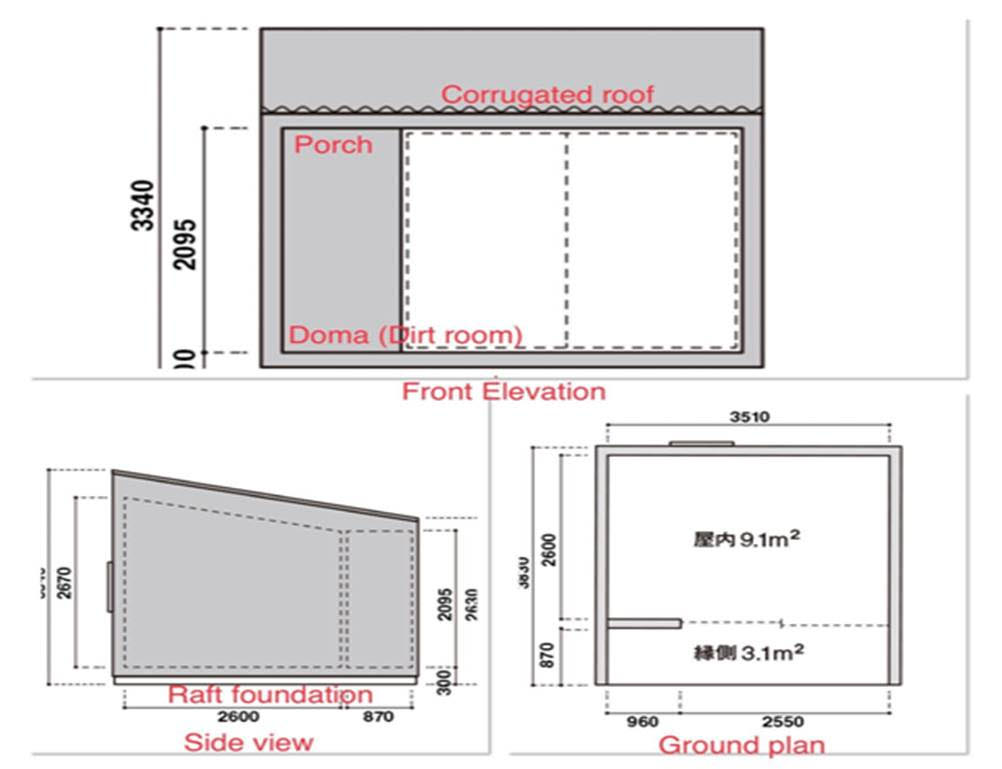

The MUJI Hut, which costs nearly $26,340 USD, covers an area of barely 100 square feet and is available only in Japan. It was released in autumn, 2017. The cabin is given a shed style roof because of the steeper slope which is effective in water-shedding. It has a foundation of asphalt. The material used is a corrugated sheet as it is lighter and easy to build which also helps in mobility. This style uses less material which makes it more cost-effective. The angular roof increases the amount of natural light entering the house. The simplicity of the roof also resembles a traditional look (Fig. 2).

It has a raft foundation which is generally used in common houses. Raft foundation helps the soil which has low bearing capacity also supports heavy structural loads. It also provides stability and protects from ground moisture.

The big sliding door enhances the natural light and glamour of the surroundings. It’s a glass door with a rectangular metal frame. The high-quality use of the material and strategically placed window makes it more convenient to adjust with interiors. The sliding door and a small window are made of the aluminum sash. Single-layer glass and insulation and polyethylene foam. The porch and slant roof makes the space airy and open. The furniture resembles traditional motifs resembling the chimney and carpet. The interior also contracts with linear and conventional types of furniture.

Economical context (costs)

The prefab house is only available in Japan. It costs nearly $26,340 USD with base (includes tax and operating costs of the construction installation). Insulations and electrical outlets are optional add ons. The hut is sold unfurnished and without plumbing.

There may be an additional charge for the application of construction approval, also climate conditions at the construction site can cause extra costs. The warranty covers the hut for one year and the building frame for five years, though it can be assured that MUJI will last long. Affordance exists even if they are not visible. The furniture is sold separately. The second point which people consider is no kitchen and washroom. A structure is provided without two basic things.

Ergonomics and Aesthetics

As shown in (fig. 3) the ground plan, front elevation and side view of MUJI Hut is shown with dimensions. The rectangle area before the entrance door is doma (dirt room). The roof is interpreted as a thick corrugated sheet. The plinth (raised platform) is kept and then the cabinet starts. Section of the cabinet demonstrates the emptiness of the space.

The mortar floor gives resistance, durability, and longevity. It can be used like an earthen floor even in dirt prone areas. The surface is nice and smooth and easy to clean. As shown in the front elevation (fig. 3) and ground floor the interior layout is 9.1 meters square. The porch is a 3.1-meter square that can be easily shown on the ground floor. The raft foundation can be easily illustrated in the side view. Side view (fig. 3) says about the roof angle which allows the maximum light also the dimension which is in meter square helps to understand the space in depth.

In the ground-plan, it is clearly seen that there is an opening for the chimney. The MUJI hut reflects ergonomics with respect to the material and aesthetics. Space covered the ergonomics as well as the traditional values.

Relation with Japanese craft and design

The inspiration for the cabin was taken from “shakkei” a Japanese traditional landscaping technique. It denotes background borrowing which blends the charm of the surrounding. The external roof and wall of the cabinet are layered with “sho sugi ban”. (Actually called “yaki sugi” in Japanese). It’s a conventional skill that burns the surface of cedar wood which adds stability, solidity and distinct textures.

Engawa (fig. 4) is a corridor that connects the interior space with natural surroundings. Traditional Japanese houses don’t have fixed walls, instead, they have “inner partitions”, or shoji. This technique consists of translucent material over a wooden frame and the outer walls, these were known as storm shutters. The inspiration for the sliding door is from Shoji and Amado (storm shutters).

Drawbacks/ How could it be improved.

The cost of the cabin is still high-priced. One of the major drawbacks is that the hut has no supply for electricity or plumbing. Hence you need to search for the facility which provides a kitchen and bathroom. As a solution, MUJI is trying to do a collaboration with TOTO: The largest bathroom fittings and sanitary ware manufacturer. MUJI will attach a bathroom and also a kitchen pod to get rid of the As this was the first prefab product of MUJI the idea was to make a simple cabin with the least furniture and interior details.

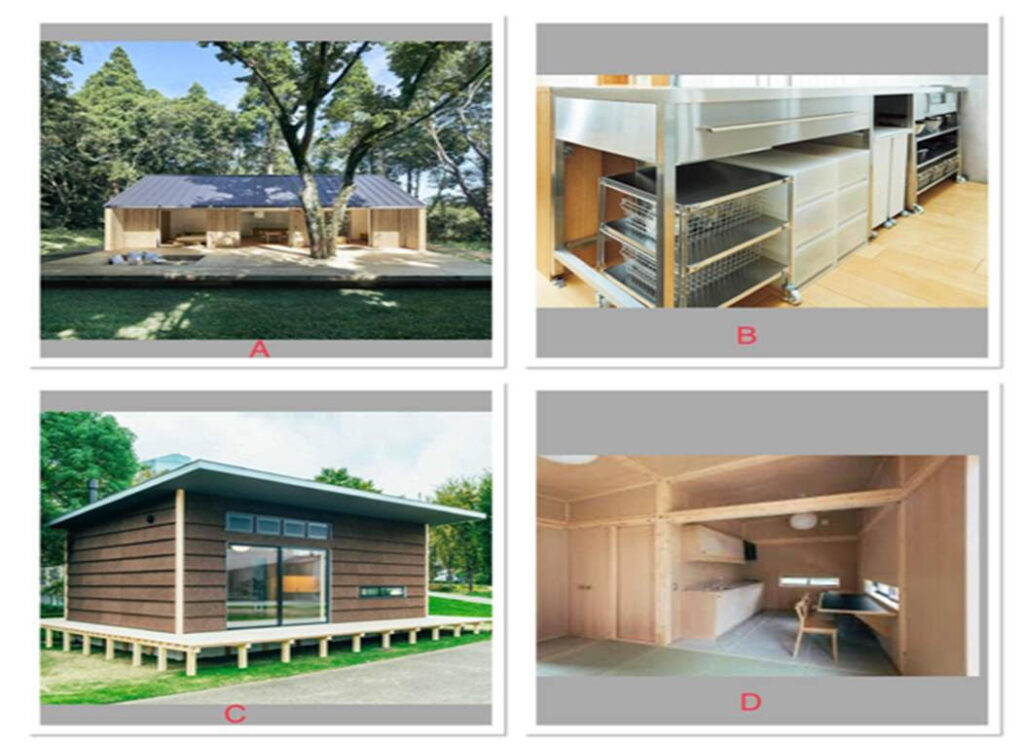

This was the temporary solution Naoto gave for MUJI hut. Different reviews helped to know what consumers’ various actual problems. Two things were missing – Cost and Consumers Requirements. MUJI in his second version of the prefabricated houses focused on the drawbacks and launched two other houses that were worth buying. Grcic’s MUJI hut and Yo no le (plain) house. Grcic’s hut (fig. 5) is an advanced version of the MUJI hut with a small kitchen and attached washroom. Yo no le (fig. 5) provides larger space and was made for retirees. It was spread around 200 square feet and encouraged indoor-outdoor living. The yo no le house consists of all the furniture designed by MUJI. MUJI currently sells around 300 prefab houses yearly and the demand is growing day by day. The new version of MUJI product incorporates the drawbacks and Yo no le is an example of it.

Conclusion: How To Deal With The Housing Problems

Hence the prefabricated houses can be a solution to many housing problems. MUJI Hut is one of them. Hence many problems can be solved through the idea of prefabrication. The Yo no le or plain houses are made to encourage indoor-outdoor living. The single-story home enables you to interact with nature that is difficult in urban areas. Prefabrication can design buildings more environmentally -friendly. Financial savings, flexibility and shorter construction time are major benefits. It also reduces the cost behind contractors and staff. Since most of the elements are assembled in the industry there is less risk of environmental hazards and dirt. Also, indoor construction prevents from on- the- job-injury.

There are a lot of benefits of prefabrication but it’s just there is less awareness of prefab construction. Countries like Singapore have widely adopted this technology. In India, there is just the beginning even though there are few large projects happening and shortly the prefabricated construction technique would be available in India.

By: Akshat Shah

Write and Win: Participate in Creative writing Contest & International Essay Contest and win fabulous prizes.