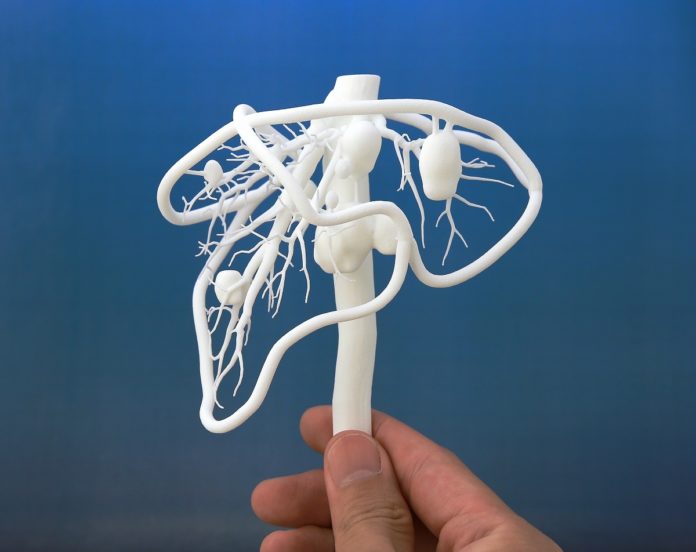

In the last decade, many technological advancement has been made and 3D-organ printing is among them. First of all, we need to learn what organ printing is? A printable organ is an artificially constructed device which is designed for organ replacement, produced using 3D printing techniques. The current and ongoing research into 3D-bio printing or 3D-organ printing application generates huge interest and excitement. It is extremely broad both geographically and on in its focus and aims. Even if it was not discovered so early but it has been developing at a very good rate. 3D-printing was first introduced in 2003 for producing a cellular construction when Thomas Boland of Clemson University patented the use of inkjet printing for cells. Today, the primary purpose of printable organs is in transplantation on artificial heart, kidney and liver like structures, as well as other major organs. For more complicated organs, such as heart valves have also been the subject of research. Some printed organs are approaching functionality requirements for clinical implementation, and it also includes hollow structures such as bladder as well as vascular structures such as urine tubes.

Organ printing has been approached as a potential solution for global shortage of donor organs. Organs that have been successfully printed and implemented in a clinical setting to help the doctors and the organ donors are either flat, such as skin, vascular, such as blood vessels or hollow, such as the bladder. When artificial organs are prepared for transplantation, they are often produced with recipients own cells. 3D-organ printing allows for the layer-by-layer construction of a particular organ structure to form a cell scaffoid. This can be followed by the process of cell seeding, in which the cells of interest are pipette directly onto the scaffoid structure. Additionally, the process of integrating cells into the printable material itself, instead of performing seeding afterwards, has been expired. Now, modified inkjet printers have been used to produce three dimensional biological tissues. Printer cartridges are developing and so they are now filled with a suspension of living cells and a smart gel, the latter used for providing structure.

For manufacturing of artificial organs by 3D-organ printing has been a major topic of study in biological engineering. As a result, the rapid manufacturing techniques entailed by 3D-organ printing become increasingly efficient, their applicability in artificial organ synthesis has grown more evident. This allows for the creation of constructs that are more effective in resembling the microstructure of a natural organ or tissues structure.

There are mainly two types of bio-printing. First one is drop-based bio-printing or inkjet bio-printing. In drop based bio-printing cellular construction is done using droplets of a designated material, which has often times be combined with a cell line. It is used for its efficient speed. The other one is exctrusion bio-printing. Extrusion bio-printing involves the constant deposition of a particular printing material and cell line from an extruder, a type of mobile print head. Its speed is slower as compared to drop-based bio-printing, so it is not used commonly for its slower speed.

Materials also play an important role for the 3D-printing. Materials for 3D-printing usually consists of alginate or fibrin polymers that have been integrated with cellular adhesion molecules, which support the physical attachment of cells.

Organ-printing has been developing at a very good rate and according to the P and S market research, the 3D bio-printing industry was valued at $98.6 million in 2015. This is expected to grow at 35.9% CAGR between 2016 and 2022 with a number of companies commercially there is also a development in 3D bio-printing process and technology. These include Envisionstec, BioBots, Organovo, Lellick, Ourobotics, Ather etc. In the long run of these companies, Organovo is perhaps the most prominent company conducting research into the 3D bio-printing process for line tissues and 3D printed organs, at least in terms of media coverage.

At last we can say that, 3D bio-printing has a major impact on human life and human future. It has given a new opportunity to the future biological engineers and to many companies to develop and to make the human life better for the future.

Author: ADITYA SINGH, CLASS: -11, Karimganj, Assam, a participant of Monthly Essay Competition, September-2018