This seemingly easy task often takes hours to attain a perfect finish; however, one might say that a flawless finish hinges on selecting the proper spray equipment and using it skillfully. The many spray gun types available address specific applications and materials. A good grasp of these subtle differences among the various types of spray guns can only assure professionals and DIY personalities alike that the desired results could be achieved, minimum waste of materials enjoyed, and a particular level of quality attained.

The spray gun chosen can really influence the speed, efficiency, and final appearance of any coating project, be the traditional air-powered gun or the newer electric version. This article will describe the main different types of spray guns with special reference to their salient features and modal applications across Canada.

Those contemplating investing in the first-class spraying tools can find spray equipment for sale in Canada to be very reliable. Spray guns from countless suppliers across the country include an entry-level model for occasional users to a high-end professional system for highly demanding industrial users. Whether you’re an automotive refinish painter in Vancouver looking for a new HVLP gun or a contractor in Calgary searching for an airless sprayer to paint homes on a large scale, the spraying equipment necessary to do the job here in Canada has reasonably adequate availability. A thorough investigation of the offerings from Canadian distributors who are reputed ensures one gets equipment that conforms to the local safety standards, plus the performance and durability required for the next coating job.

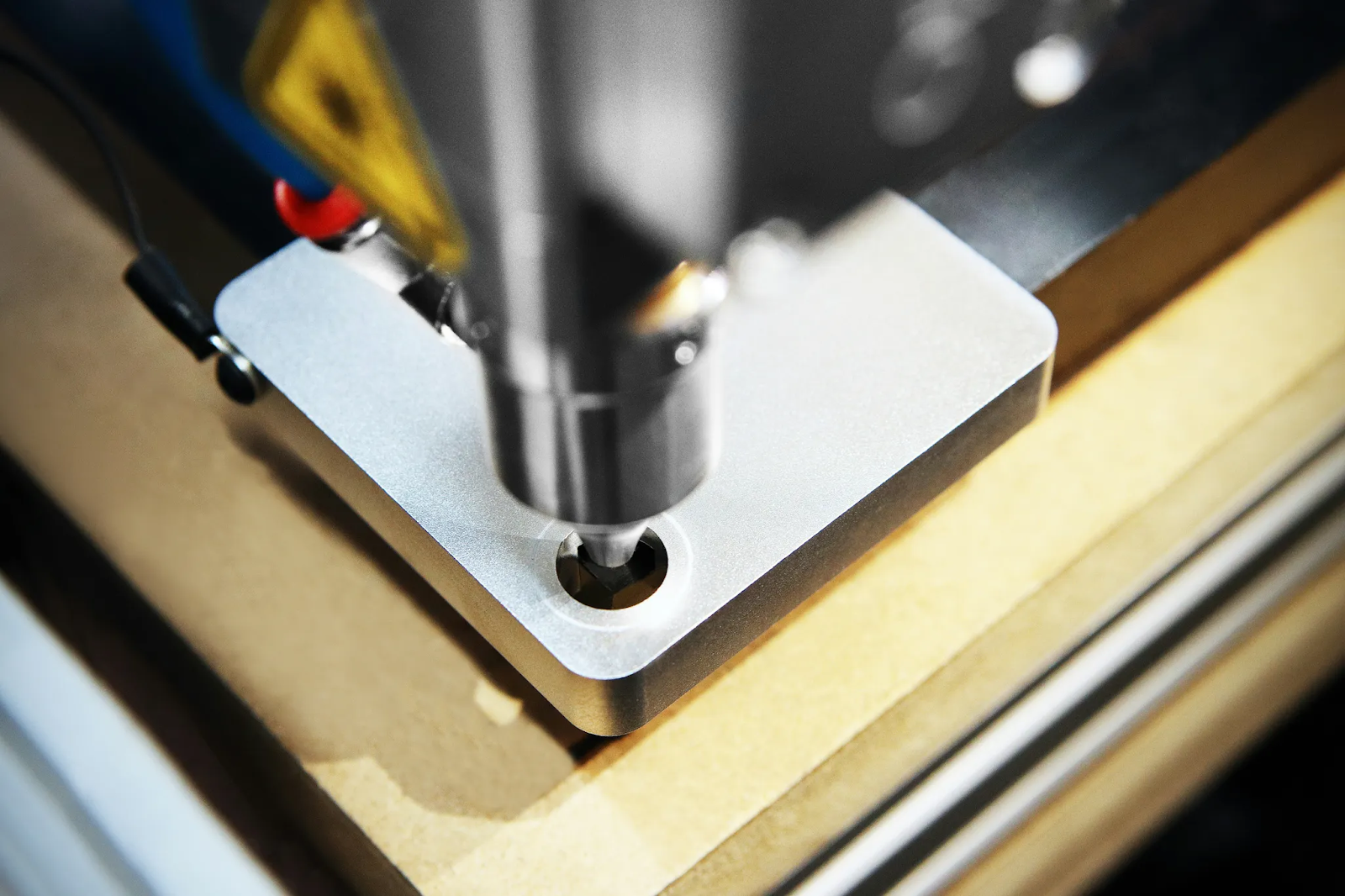

One of the most common is the air spray gun, which depends on compressed air for atomizing the coating material and propelling it in the designated direction. Within this category, the HVLP guns stand out as ever- popular because of their efficiency. By applying a large volume of air at low pressure to atomize paint, HVLP spray guns produce less overspray that saves material and helps reduce harm to the environment.

HVLP guns are often used in automotive painting, furniture finishing, and other applications requiring highly controlled finishing. Conventional air spray guns, on the other hand, use high air pressure to spray fairly fast, which is good for bigger surfaces and some industrial applications, though these generally have lesser transfer efficiency.

The other major category is the airless spray gun. Airless apply very high pressure to accomplish atomization, with paint being forced through a small tip, creating a fan spray pattern with no assistance from compressed air. Airless sprayers are known for their speed and efficiency in covering large areas, making them excellent for painting walls, ceilings, and exteriors of buildings. So commonly used in Canada by professional painters and contractors for residential and commercial projects, tip sizes and pressures can be adjusted to suit different coating materials and project needs.

Electrostatic spray guns are the more specialized spray guns in this category. These guns confer an electrical charge on the paint particles, while the object being painted is grounded. Charged particles are attracted to the grounded surface, facilitating extremely high transfer efficiency and excellent wrap-around coverage that minimizes overspray and material waste. Commonly, electrostatic spraying is used in industrial finishing for coating the metal parts and components of products, appliances, and automotive vehicles.

The gravity-fed, siphon-fed, and pressure-fed HVLP guns are classified by how the paint is delivered into the gun. On gravity-feed spray-gun designs, the paint cup is mounted at the top of the spray gun, with gravity forces assisting in the delivery of the material to the nozzle and often leading to better material usage and easier cleanup. In a siphon-feed setup, the cup is mounted below the gun, and a stream of pressurized air creates a vacuum to draw paint up into the nozzle. Because they can accommodate a wider range of viscosities, siphon-feed guns can often be quite forgiving when it comes to paint consistency. The pressure-feed sprays use a separate pressurized pot to supply paint in large amounts to the gun; they are ideal in applications with a continuous spray for large projects.

The choice on what spray gun to use depends on various factors: the type of material being sprayed, the scale and complexity of the job being tackled, the expected quality of finish, plus, of course, which fits the budget. By understanding all these spray guns in the spray equipment for sale in Canada, you can arrive at the right decision and achieve results that are of professional quality.

Write and Win: Participate in Creative writing Contest & International Essay Contest and win fabulous prizes.