Organ Redemption Photo : 3ders

“Believe in your heart that you’re meant to live a life full of passion, purpose, magic and miracles.”

― Roy T. Bennett, The Light in the Heart

Diseases such as advanced heart failure, cardiomyopathy, congenital heart disease, coronary artery disease are severe medical conditions which require a heart transplant. A heart transplant can enhance the quality and length of life of the patients with these severe heart diseases.

However, the waiting list for heart transplant patients is becoming longer day by day and waiting time has increased as well. Twenty people die every day waiting for transplant in The United States alone and every ten minutes, another person is added to the waiting list in The United States. This crisis correlates to the life boat dilemma. How many people can be allowed to board an already overcrowded life boat without sinking the boat and with everybody on board? Donor hearts are scarce. Fortunately, this dark cloud has got a silver lining called 3D printing.

3D printing is process of making a physical three-dimensional object by laying down several thin layers of a material by computer aided design. Invented by Chuck Hull, this magnificent technology is employed in a variety of industries today. Be it automotive, fashion or food technology. 3D printing is also known as additive manufacturing because it involves process that adds layers of materials to make an object, as opposed to subtractive manufacturing which involves removing sections of a material by cutting it away. This applied science witnessed several breakthroughs and advancements continually. Today, a basic 3D printer costs around INR 2,00,000. The increased affordability and accessibility of the device makes it possible to imagine a future where 3D printers are kept next to our fridges.

Healthcare industry has welcomed 3D printing more enthusiastically as compared to other industries. Doctors have been using scanned data to build 3D representation of patients’ inside since a very long time. This technology seems very promising in the field of health care. Although it is not clinical ready yet, research is continually progressing in areas such as wound healing and tissue bioengineering, generating a possibility that we can engineer hearts in future.

For tissue bioengineering, collagen is a desirable material. Collagen is the most abundant protein in animals which forms primary component of extra cellular matrix. Almost every single tissue in our body has collagen! However, collagen is fluidic in nature. Successive layers of collagen would eventually collapse in air and form just a puddle. This posed as a major difficulty unless FRESH came into the picture.

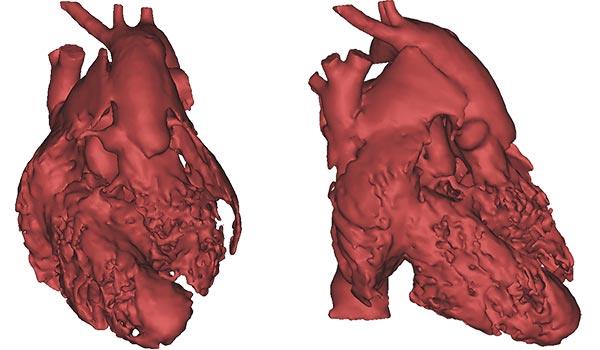

Scientists have developed a technique called Free form Reversible Embedding of Suspended Hydrogel (FRESH). With the help of FRESH, soft cell encapsulated materials such as collagen get temporary support and keeps it solid at room temperature. And this temporary support gets dissolved as the tissue progresses from room temperature to body temperature. In addition, it also makes unprecedented resolution possible. Patient specific anatomical structures such as small blood vessels, valves and beating ventricles can be accurately produced using 3D printing and FRESH.

We have come a long way but there’s still a long way to go. A lot of challenges still remain. For instance, speed. Printing process is time consuming. Current speed is many notches below the commercial acceptable level. Another challenge is controlling cell fate. Stem cells are used for 3D printing which are multipotent i.e. they can differentiate into different types of cell. However, presently we do not fully understand what determines the fate of the stem cell. Consequently, we face challenge in controlling the fate of cells. Vasculature of the organ poses another road block. Each organ has a network of blood vessels surrounding it which provides it with oxygen and nutrients and eliminate toxic waste products. Diffusion is insufficient for organs which are several layers thick. This makes vasculature all the more necessary. We lack the solution to this problem presently. And at last, there are various ethical issues about use of 3D printing in healthcare which address questions such as if the technology is only for the rich, how can we test that the treatment is safe and effective before implementing clinically and should we use 3D printing for human enhancement. For example, replacing natural organs with engineered ones for more efficacy.

But future prospects of bio-engineering hearts paint a rosy picture and help us visualise a world with less pain and agony. The patients waiting for heart transplants won’t have to wait for donor hearts. Millions of lives would be saved and benefitted. The very long waiting list of patients would be shortened. Life expectancy and health standards would rise to remarkable levels if 3D printed hearts are implemented clinically.

Writer Bio- Prateek Goyal, 18 years old student from Delhi. A participant of International Essay Contest, August, 2019 organized by #Monomousumi_Services