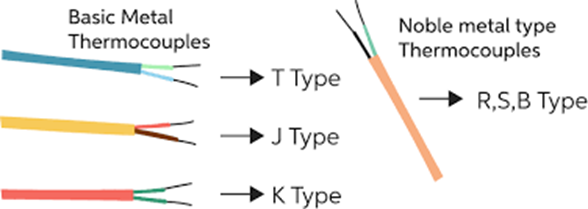

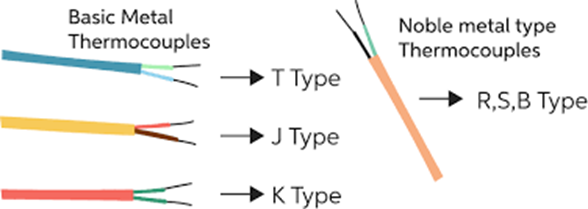

Thermocouples are widely used in the field of temperature measurement and control, and are particularly valuable in industrial applications where accuracy and reliability are crucial. A thermocouple is a device that consists of two different metals that are joined together at one end. When a temperature difference exists between the two ends of the thermocouple, a voltage is generated that is proportional to the temperature difference. The voltage is then measured and used to calculate the temperature. In this article, we will discuss the different types of metal thermocouples and their characteristics.

Metal Thermocouples play a vital role in temperature measurement and control, especially in industrial settings that require precise and dependable readings. These devices are composed of two dissimilar metals that are connected at one end. As the temperature varies between the two ends of the thermocouple, a corresponding voltage is generated, which is directly proportional to the temperature difference. The voltage is then measured and converted into temperature readings. There are various types of metal thermocouples and their unique properties.

Type J Thermocouple

The type J thermocouple is made of iron and constantan, and has a temperature range of -210°C to 760°C. It is commonly used in industrial applications such as furnaces and ovens. One of the advantages of the type J thermocouple is its low cost, but one of the disadvantages is that it is not suitable for high-temperature applications.

Type K Thermocouple

The type K thermocouple is made of chromel and alumel, and has a temperature range of -270°C to 1,370°C. It is the most commonly used thermocouple and is suitable for a wide variety of applications such as heating and cooling systems, and food processing. One of the advantages of the type K thermocouple is its high accuracy, but one of the disadvantages is that it is not suitable for high-temperature applications.

Type T Thermocouple

The type T thermocouple is made of copper and constantan, and has a temperature range of -270°C to 400°C. It is commonly used in low-temperature applications such as refrigeration and cryogenics. One of the advantages of the type T thermocouple is its high accuracy, but one of the disadvantages is that it is not suitable for high-temperature applications.

Type E Thermocouple

The type E thermocouple is made of chromel and constantan, and has a temperature range of -270°C to 1,000°C. It is commonly used in applications such as plastics, food processing, and pharmaceuticals. One of the advantages of the type E thermocouple is its high accuracy at low temperatures, but one of the disadvantages is that it is not suitable for high-temperature applications.

Type N Thermocouple

The type N thermocouple is made of nicrosil and nisil, and has a temperature range of -270°C to 1,300°C. It is commonly used in high-temperature applications such as gas turbines and aerospace. One of the advantages of the type N thermocouple is its high stability at high temperatures, but one of the disadvantages is that it is more expensive than other types of thermocouples.

Type R and S Thermocouples

The type R and S thermocouples are made of platinum and rhodium, and have temperature ranges of 0°C to 1,600°C and 0°C to 1,400°C, respectively. They are commonly used in high-temperature applications such as metal refining and ceramics. One of the advantages of the type R and S thermocouples is their high accuracy at high temperatures, but one of the disadvantages is that they are more expensive than other types of thermocouples.

Type B Thermocouple

The type B thermocouple is made of platinum and rhodium, and has a temperature range of 0°C to 1,800°C. It is commonly used in high-temperature applications such as furnace and kiln monitoring. One of the advantages of the type B thermocouple is its high accuracy at high temperatures, but one of the disadvantages is that it is the most expensive type of thermocouple.

In Conclusion

Thermocouples are used in a wide range of applications, from industrial to scientific, and choosing the right type of thermocouple for the job is crucial. Each type of thermocouple has its own characteristics and advantages and disadvantages. It is important to consider factors such as temperature range, accuracy, stability, and cost when selecting a thermocouple. Understanding the different types of metal thermocouples can help ensure that the correct thermocouple is selected for the job, resulting in accurate and reliable temperature measurement and control.

Write and Win: Participate in Creative writing Contest & International Essay Contest and win fabulous prizes.