Global trade is undergoing a structural transformation that is reshaping how goods are manufactured, shipped, and delivered. For decades, long-distance supply chains defined international commerce, relying on low-cost production hubs and complex shipping networks to meet global demand. Nearshoring, relocating production closer to end markets, is redrawing the map of freight movement. Driven by changing economic priorities, geopolitical pressures, and technological advances, this shift is creating new opportunities and challenges for logistics providers, manufacturers, and policymakers alike.

Shifting Supply Chains and the Rise of Regional Trade

The traditional model of globalized production depended on lengthy, cost-optimized supply chains that stretched across continents. While efficient on paper, these systems have revealed vulnerabilities in recent years. Disruptions caused by pandemics, natural disasters, trade disputes, and geopolitical tensions exposed how fragile long supply chains can be.

In response, companies are reassessing their strategies and moving production closer to consumer markets, fueling a wave of regionalization. This approach positions nearshoring the future of freight, as shorter and more resilient supply chains reduce risks while maintaining competitiveness. Regional trade agreements and infrastructure investments are accelerating this shift.

North America, for example, has seen increased manufacturing activity in Mexico, leveraging proximity to the U.S. market. Similar dynamics are emerging in Europe and parts of Asia, where neighboring countries are forming integrated production zones to minimize shipping distances and maximize logistical efficiency. This realignment is fundamentally altering freight routes, transportation modes, and distribution networks.

Reducing Transit Times and Transportation Costs

One of the most immediate benefits of nearshoring is the reduction of transit times. Traditional overseas shipping often involves weeks of transit by ocean freight, followed by inland transportation to reach final destinations. Nearshoring allows companies to use shorter shipping lanes and more flexible transportation options, significantly cutting lead times. This is valuable for industries where rapid response to market changes or seasonal fluctuations is crucial.

Shorter distances can translate into lower transportation costs. While labor costs in nearshore markets may be higher than in offshore manufacturing hubs, savings in logistics, reduced inventory holding, and improved supply chain agility often offset these differences. For logistics providers, this shift creates new opportunities to optimize multimodal transport strategies, integrating trucking, rail, and short-sea shipping to support regional supply chains more efficiently.

Strengthening Supply Chain Resilience

Global supply chains proved vulnerable to shocks during events like the COVID-19 pandemic, the Suez Canal blockage, and trade conflicts. Nearshoring enhances resilience by shortening supply lines and diversifying sourcing locations. Companies can better control production processes, respond quickly to disruptions, and reduce dependence on single points of failure.

Regional supply chains make it easier to manage regulatory compliance, quality control, and communication between suppliers and buyers. Proximity fosters closer collaboration, allowing businesses to adjust production and shipping schedules in real time. This flexibility is increasingly valued in industries where market conditions shift rapidly, such as electronics, automotive manufacturing, and consumer goods.

Changing Freight Routes and Infrastructure Demands

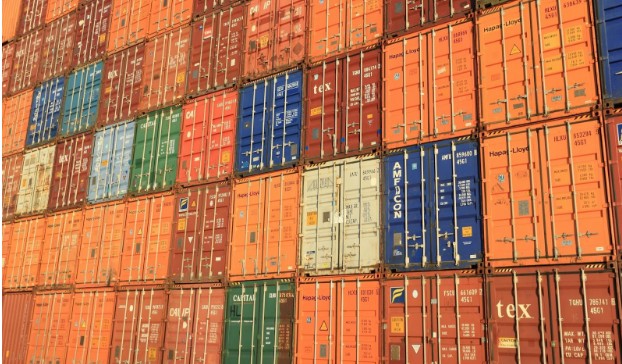

As production moves closer to end markets, freight corridors are shifting accordingly. Ports that once served as primary gateways for long-haul container shipments may experience reduced volumes, while regional ports and inland hubs gain prominence. Increased cross-border trucking, short-sea shipping, and rail freight between neighboring countries are becoming central to nearshored supply chains.

This evolution places new demands on transportation infrastructure. Highways, bridges, and rail networks must be upgraded to handle increased regional freight flows. Logistics hubs near borders and regional manufacturing centers are expanding to accommodate greater cargo volumes. Governments and private companies are investing in modernizing customs systems, streamlining border procedures, and integrating digital technologies to support seamless regional trade.

Environmental and Sustainability Benefits

Nearshoring can deliver substantial environmental benefits by reducing the distance goods travel, which in turn lowers greenhouse gas emissions from transportation. Long-haul ocean freight, while efficient per unit, still contributes significantly to global emissions. Replacing part of this movement with shorter routes, trucking, or rail can reduce carbon footprints when paired with investments in cleaner transportation technologies.

Many companies are incorporating sustainability goals into their supply chain strategies. Nearshoring supports these efforts by enabling closer monitoring of production practices, easier implementation of green initiatives, and the use of more sustainable logistics modes. As regulations and consumer expectations around environmental responsibility grow, nearshoring offers a practical way to align economic and sustainability objectives.

Implications for Logistics and Workforce Development

The nearshoring trend is reshaping logistics strategies and workforce needs. Logistics providers must adapt to new freight flows by rethinking network design, investing in technology, and developing expertise in regional trade regulations. Distribution centers may shift closer to key consumer markets, while greater reliance on cross-border trucking requires efficient coordination between carriers and customs agencies.

Workforce development is another critical factor. As nearshoring drives regional manufacturing growth, demand for skilled labor in both production and logistics is rising. Workers trained in advanced manufacturing, warehousing technology, and supply chain management are crucial to support this evolving ecosystem. Public-private partnerships and targeted training programs can help address labor shortages and ensure the workforce is prepared for new supply chain models.

Strategic Considerations for Businesses

Businesses evaluating nearshoring must weigh several strategic factors to ensure success. Cost remains a key consideration, but it must be analyzed holistically. While production costs may rise, savings from reduced shipping times, improved resilience, and lower inventory requirements can make nearshoring economically advantageous. Companies should conduct detailed cost-benefit analyses that factor in transportation, tariffs, risk mitigation, and customer service levels.

Another crucial element is selecting the right nearshore location. Factors such as infrastructure quality, political stability, labor availability, and regulatory environments all influence success. Building strong partnerships with regional suppliers, logistics providers, and government agencies helps smooth the transition and maximize the benefits of nearshoring. Companies that take a proactive, strategic approach can position themselves to thrive in this evolving landscape.

Nearshoring is transforming the geography of freight movement, shifting trade patterns toward shorter, more resilient, and environmentally sustainable supply chains. By reducing transit times, strengthening infrastructure, supporting sustainability goals, and fostering regional economic integration, nearshoring is setting the stage for a new era in global trade. Businesses that embrace this shift strategically will gain a competitive edge, while logistics providers and policymakers play a vital role in building the infrastructure and workforce to support this transformation. The future map of freight is being redrawn, not by chance, but by deliberate adaptation to a changing world.

Write and Win: Participate in Creative writing Contest & International Essay Contest and win fabulous prizes.