In industries, welding is a process that necessitates precision and care. While welding does require proficiency and diligence, it equally emphasizes the importance of safety. Welders face dangers like burns, electric shocks, and exposure to fumes. Protectiveness in welding includes safeguarding both the welder and the work area. This article delves into safety measures in welding aimed at preserving well-being and boosting efficiency.

Personal Protective Equipment (PPE)

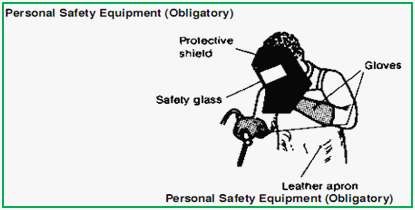

Ensuring you wear protective gear (PPE) is crucial for staying safe while welding work is being done. Welding fume extractors, helmets, gloves, and protective clothing are items of PPE that should be worn. Helmets offer protection for your eyes and face from sparks and dangerous radiation. Gloves are important for shielding your hands from heat and sharp materials. Protective aprons and boots are essential for safeguarding your body against metals and falling debris.

Workspace Ventilation

Having ventilation in the welding area is really important to keep everyone safe and healthy! When you weld stuff together, it produces fumes that can be bad for your lungs and overall breathing system. To make sure these fumes don’t stick around long and hurt anybody’s health, we need to have airflow in the area. One way to do this is by setting up systems that suck out the air or using fans that can move the air around. It’s also a good idea to check on these ventilation systems very often to make sure they are working well and keeping everyone safe in the long run!

Fire Prevention Measures

Welders frequently produce sparks that have the potential to ignite materials that can easily catch fire in the workplace, setting it ablaze. It is crucial to take steps to lower the risk of fires occurring by removing any items that could easily catch fire and cause an emergency. Keeping fire extinguishers within reach is important for being prepared in case of any incidents.

Electrical Safety Precautions

Electricity is crucial in the welding process. Ensuring safety is very important here too! Making sure that equipment is properly grounded lowers the chances of getting a shock while working with it. Regularly checking cables and connections can help detect any issues early and prevent accidents down the line. Remember to be cautious when handling tools near wet surfaces to avoid any mishaps.

Proper Training and Certification

Training continues to be an aspect of ensuring safety in welding practices. Thorough education provides welders with the knowledge to operate equipment safely. Certified training courses address subjects such as recognizing hazards and responding to emergencies. Continuous learning helps keep welders informed about industry regulations and advancements.

Maintaining Equipment

Ensuring that welding tools and machinery are well-maintained is key to safety in the workplace! Regular checks help prevent equipment issues and lower the chances of accidents occurring. Cleaning tools to remove any debris that may impact performance is essential. Inspect parts for signs of wear and tear to ensure everything operates safely. Giving priority to equipment maintenance boosts reliability and reduces safety risks significantly.

Ergonomics and Comfort

Focusing on ergonomics is important for creating a more comfortable workplace environment where proper posture and positioning help avoid strain and tiredness. Adjustable tools and supportive chairs improve comfort during hours of welding work. It’s also beneficial to take breaks to give muscles a chance to rest and lessen the chances of strain injuries.

Emergency Preparedness

It’s crucial to be ready for situations when it comes to staying safe while welding. Creating defined emergency strategies helps in reacting in case of accidents. Regularly practicing emergency protocols helps team members get accustomed to them and improves readiness. Having first aid kits readily available makes treating injuries possible.

Fostering a Safety Culture

Fostering an environment that puts an emphasis on safety is advantageous for all those engaged in welding activities. Empowering dialogues regarding safety issues promotes teamwork and effective solutions. Appreciating and acknowledging safe behaviors encourages individuals to make safety a primary focus.

Conclusion

Ensuring safety while welding is an effort that relies on the dedication of all parties involved in the process. To minimize risks effectively and create a safe working environment, it is essential to be aware of dangers, use the right protective equipment, and uphold proper safety measures. Critical elements such as receiving training, regular maintenance of equipment, and promoting a culture of safety are factors in safeguarding individuals and their surroundings. Prioritizing safety not only reduces the likelihood of accidents but also boosts efficiency and well-being within the welding sector.

Write and Win: Participate in Creative writing Contest & International Essay Contest and win fabulous prizes.