Source: Brainhub

Lean portfolio management basically identifies ways to eliminate waste, and eliminates waste. And also, it improves workforce, and better work culture (limit work queues). And also, it has good directions. The Agile model is adaptive to change. There are shorter planning and commitment cycles. The Agile model mainly focuses on collaboration and interaction. People use these methods to get sustainable results. When those models are applied correctly, the organizations become efficient and effective. Lean manufacturing was introduced by Taiichi Ohno who was an engineer in Japan. Customer satisfaction, fulfilling the requirement and quality of the product should be considered at manufacturing a product. When a customer is satisfied with the product, he or she tends to buy them. And also, they encourage others to buy it. Most of the customers consider the quality of the products. Manufacturing quality products can lead to more profits. When the quality of the product is increased, cost is also increased. Some services and products don’t require quality. Example: mousetrap. Such kinds of products don’t require quality. Fulfilling the customer requirement is enough. In those cases, the cost which is used to improve the quality of product, can be cut down at manufacturing. Manufacturers should make sure to fulfill the requirements of customers. When customers are satisfied, it is beneficial for producers. Therefore, businessmen and producers use principles such as Lean portfolio management and Agile model to improve their products and services. When these principles are followed, productivity of an organization can be increased.

Lean portfolio management

There are seven core concepts of lean portfolio management (lean principles). Those are:

- eliminating waste

- empowering the team

- delivering fast

- optimizing the whole

- build quality in

- defer decisions/ decide late

- amplify learning.

Waste is eliminated to maximize value. Partially done work, extra features, extra processes, waiting, task switching, defects, motion are categories of waste. Partially done work is the started work which is not complete. Extra processes are the extra work which value is not added. Example: approvals that are not necessary (unnecessary approvals). Extra features (nice to have features) are the features that are not required and are not requested. People who are involved in multiple projects, do task switching. People have to wait for approvals and reviews. Example: waiting for document approval. Motion is the required effort to communicate from one group to another group. Example: due to distributed teams. Defects are the defective software or documents that corrections are required. Example: requirement defects. General guidelines are given to avoid mistakes at empowering the team. There should be a good direction. Otherwise, they can’t achieve their goals. Required project solutions are delivered to stakeholders in incremental ways at delivering fast. All modules that connect to project solutions are focused at optimizing the whole. Customer’s value is kept in mind at building quality in. it is the value that the workforce wanted to implement. And also, this optimizes solutions. More informed, more relevant and engaged decisions can be taken, when business and time permit to delay decisions. Decision-making should be done carefully. Otherwise capital, money and other resources are wasted. Amplify learning is learning from the ground and getting feedback from the workforce. Listening should be done from a content point of view and emotional point of view. When the workforce is efficient and effective, high production can be achieved in a short time period. Therefore, requirements of customers as well as requirements of the workforce should be fulfilled. Then they can work hard. Therefore, getting their feedback are essential. Quality assurance and high level of efficiency are there in the Lean model. Reduction of stock and reduction of cost are objectives of the Lean model. Fewer resources are used, in order to eliminate waste. And also, the organization should be able to supply the demand. Value stream flow and customer value is identified, and lead time is reduced at the methodology of Lean portfolio management.

Lean governance, agile portfolio operations, strategy and investment funding are the dimensions of this method.

Advantages of Lean portfolio management.

- Managing team.

- Business processes become more efficient.

- Management of changing priorities is better.

- Visibility of projects is better at the team level.

- Team productivity has increased.

- Lead time is decreased.

- Team morale is high.

- Visibility to stakeholders is increased.

- The costs are reduced.

- Delivery of customer value is predictable.

- Overall productivity is high.

- Easy management.

- Production is quick.

- Flexibility.

Disadvantages of Lean manufacturing.

- Long term commitment is required.

- The process is very risky.

Agile model.

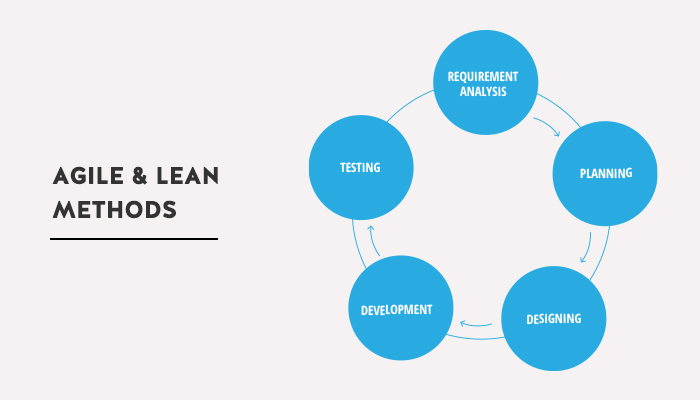

Everyone has specific tasks in the Agile model. Scrum process, retrospective, sprints, consistency, continuous delivery, continuous integration are seen in the Agile model. Adjustments are made, according to customers’ feedback. Some work can be automated. An Agile model is a set of principles and values. Marker sensitivity, process integration, a shared virtual network and flexibility are there in the Agile model. It relies on the information directly from the market.

12 principles of Agile model.

- Fulfilling customer satisfaction by continuous and early delivery of valuable software.

- Welcome changing requirements.

- Frequent delivery of working software.

- Businessmen and developers work together daily throughout the project.

- Building projects around motivated individuals.

- Encouraging face-to-face conversation.

- The primary measure of progress is working software.

- Promoting sustainable development.

- Paying attention continuously to technical excellence, and agility is enhanced by good design.

- Simplicity.

- Self-organizing teams.

- Giving regular intervals

The organizations and businesses should be able to supply the demand. Agile process gives the priority to satisfy customers through early and continuous, valuable software delivery. Agile process tries to fulfill changing requirements of the customers. And also, working software is delivered frequently. Business people, developers and stakeholders work together throughout the project. Then efficiency and effectiveness of the task is high. The required environment and needs are facilitated or given to motivated individuals. Because the environment is suitable and the needs are fulfilled, they work well. Face-to-face conversation is used to convey information within a development team. And also, this is the most efficient and effective method to convey information. The ideas can be obtained directly from this method. Good designs always enhance agility. People pay attention to technical excellence in the Agile model. Works can be done easily and efficiently, when machines and technology are used. Then the labor requirement is less. The cost is also less. Self-organizing teams can make the best architectures, designs and requirements. People become more effective, and adjust behavior at regular intervals. Improving network infrastructure, implementing an information based supply chain, making supply chain market sensitive are done and, involving suppliers and buyers in process is happening at the methodology of Agile model.

Advantages of the Agile model.

- Multiple opportunities are given for stakeholders.

- Due to transparency, the client has a good understanding about the project.

- Delivery is early and predictable.

- Schedule and costs are predictable.

- Giving opportunity to change within a short time period such as a few weeks.

- Focusing on users and business value.

- The quality is high.

Disadvantages of Agile model.

- This model is not useful to small development projects.

Importance of Lean-Agile approaches.

Costs and risks are decreased by early testing. Visibility and implementation transparency are increased. The ability is high to address or solve evolving requirements. These processes help to manufacture quality products efficiently and effectively by reducing risks.

Similarities between lean model and agile model.

- Learning is amplified.

- Improving quality

- Improving continuously.

- Empowering people.

Differences between Lean model and Agile model.

| Lean model | Agile model |

| Concerning the optimization of production process. | Concerning the optimization of developmental process. |

| Invested in technology. | Invested in information systems, people. |

| Focus on eliminating waste, work standardization, conformance to standards.Lean manufacturing is process focused. | Focus on markets, customer satisfaction and operator self-management (to maximize autonomy).Agile manufacturing is procurement focused |

| Key measures are output measures such as cost and productivity. | Key measures are capabilities. |

| Manufacture a standard product which has a long-life cycle. | Manufacture a personalized and innovative product which has a short-life cycle. |

| Established teams are available. | Self-directed work teams are available. |

| Processes are stable | Processes are reconfigurable. |

| Product development time is in months. | Product development time is in weeks. |

| The quality of product is high at point of sale. | The quality of product is high across the product life. |

| The product is little varied. | The product is very varied. |

| There is a predictable demand. | There is an unpredictable demand. |

| Partnerships are long-term and stable. | Partnerships are clusters. |

| Profit margin is low. | Profit margin is high. |

| Physical costs are dominant. | Marketing costs are dominant. |

| Typical products are commodities at supply chain strategy. | Typical products are fashion goods at supply chain strategy. |

Conclusion:

Lean and Agile processes help to manufacture quality products efficiently and effectively by reducing risks. The goal of Lean portfolio management is delivering the maximum customer value and quality products in a short time period by reducing waste. The goal of the Agile model is delivering the right product and fulfilling the customer requirements by considering the feedback of customers. The main goal of the Agile model is responsiveness.

W.I.M.Withanage