According to Environmental Potential Agency (EPA), the slaughtered waste of animals is considered as one of the most hazardous waste. The small poultry shops located everywhere in both residential and commercial areas of developing and under developing countries are generating a lot of slaughtered waste on daily basis. It includes, feathers, blood feet, head and many other non-edible parts of chicken. Due to its organic nature the waste is very attractive to disease causing microbes, such as bacteria and virus. Some well-known pathogens most commonly found in this type of waste are salmonella, shigella, E. coli, campylobacter and pseudomonas. Due to being exposed to environment the slaughtered waste causes unwanted smell in the air and act as a breeding ground for flies. In some countries the waste is recycled (in a very unhygienic manner) to make feed for chickens which may affect the health of chickens. By consuming unhealthy chicken, we may also get infected. Moreover some of the waste is also going to water sources and causing water pollution. In other countries it is recycled to make fertilizer by compositing but it takes a lot of time (may be more than 3 months). Another problem with compositing is that it needs proper temperature and moisture to facilitate the composting microbes which is not always easy and needs technical experts to estimate the exact quantities.

In order to get rid from all the above mentioned issues of slaughtered waste and to manage the waste in a proper hygienic manner, the project is therefore intended to design an “Eco-Friendly Incinerator” which will convert the waste into useful organic fertilizer in just few minutes. It will be a small 6-feet high and 4-feet wide incinerator with an attractive and easily maintainable design.

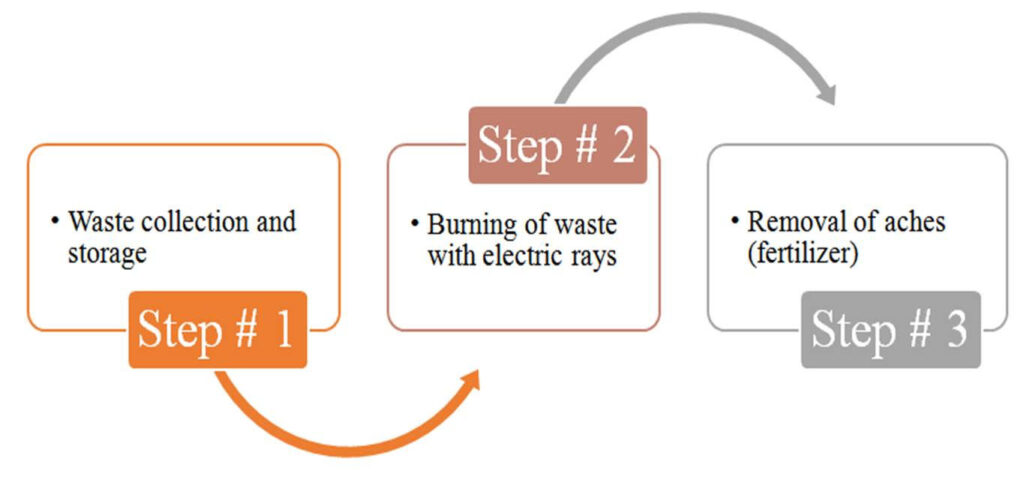

The end-users of this incinerator will the owners of poultry slaughtered shops and it will be a source of earning an extra income for shop owners as the end product of the incinerator is a fertilizer. The working mechanism of the incinerator is mentioned in details below in 3 simple steps.

Let’s explain each step briefly.

Step #1: Collection and storage:

All the waste generated during slaughtering of chickens will be collected in the incinerator and will be stored there till the end of the day. It will have the capacity of storing all the waste generated from one shop. It will have a cover so the waste will not remain expose to the environment.

Step #2: Burning of waste with electric rays:

At the end of the day the user will burn the waste by pressing the button. On pressing the button the electric rays will start burning the waste and all the waste will be converted to a reusable ash in just few minutes.

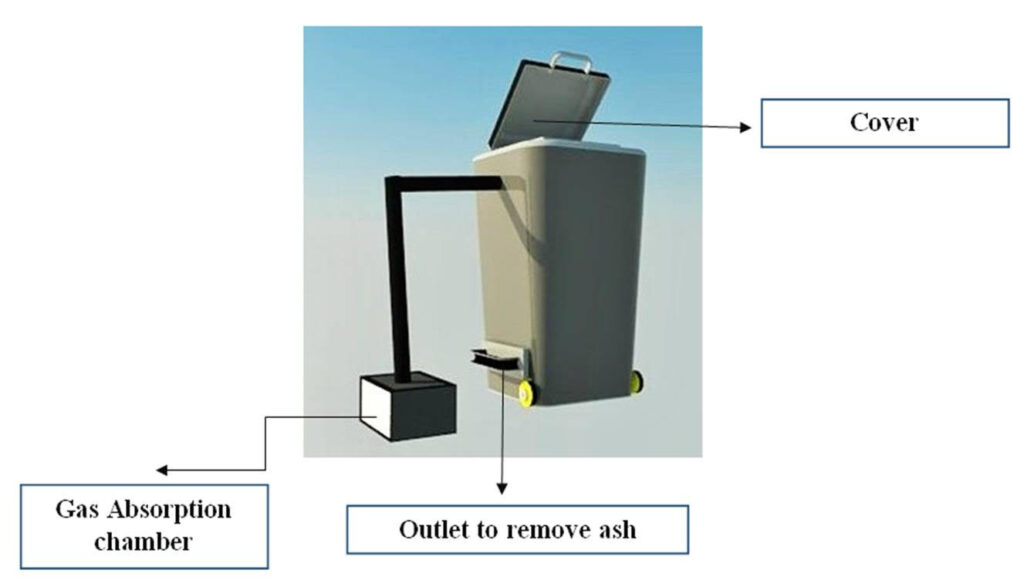

To absorb the gases (CO2, Methane CH4 and Hydrogen sulphide H2S) produced during burning of waste, a separate box (as shown in fig) will have to be attached with it which will contain Hydrogen Chloride (HCL). Hydrogen chloride is selected as an absorbing material due to having its absorbing properties.

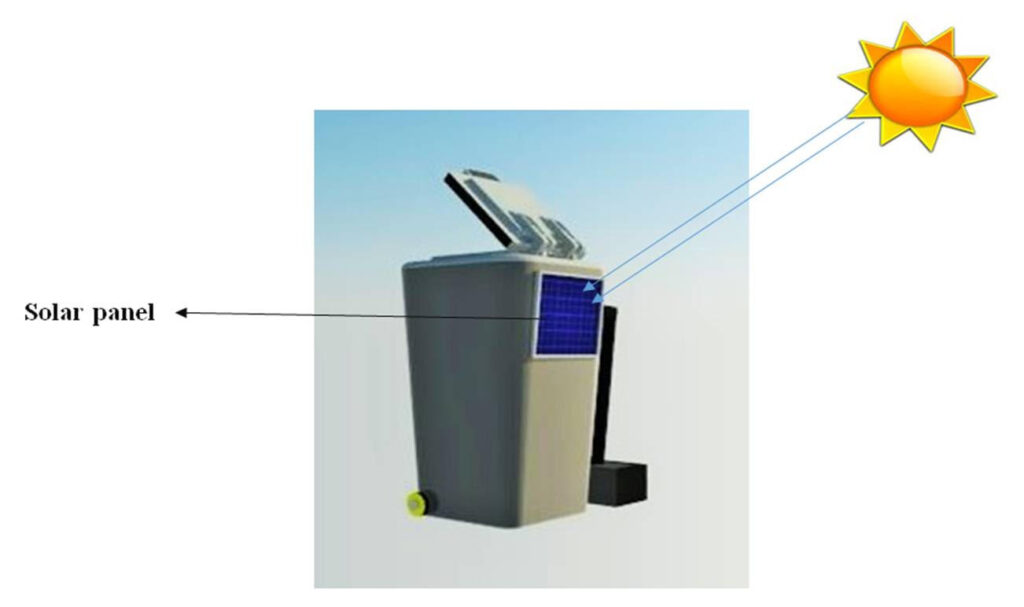

The system will have solar system attached with it so no worries for electric charges. The solar panel will convert the solar energy into electrical energy. As shown in figure 2. Solar panel will have to install south facing to get maximum exposure to sunlight. The energy will be stored in the batteries and it can be used easily on evening and night as well when sunlight will not be there.

Step # 3: Removal of ashes:

After conversion of waste into fertilizer not it’s time to remove the ashes from outlet available at the bottom of the incinerator. The fertilizer will be ready to reuse and will be free from any kind of chemicals. It will be totally organic and will not only help to grow the plants but will also be beneficial to increase fertility of soil.

In the above figures a conceptual 3d model of the incinerator is shown. The model is made by using 3d-software (Sketchup +Vray). By using this incinerator, we can get rid from all the issues of slaughtered waste and can convert it into reusable profitable product.

By Sadaf Tagar and Dr. Naveed Ahmed