Gray iron casting is one of the most widely used materials in manufacturing due to its cost-effectiveness and diverse properties. This graphite flake character is why it is gray in appearance and is a significant vibration damper with high thermal conductivity and good machinability.

Although gray cast iron has smaller tensile strength and shock resistance compared to other cast irons, it provides compressive strength close to that of low and medium-carbon steels. Grey cast iron has many applications, from engine blocks to brake components and machinery bases to pipe fittings. Market leaders in grey cast iron constantly innovate in the production process to enhance its performance and reliability in applications across various industries.

What are the processes involved in the manufacture of gray iron casting?

The manufacture of gray iron castings involves several key processes:

1. Centrifugal Casting:

Applied on cylindrical parts, molten iron is poured into a revolving mold that turns around it and forms a very dense, fine-grain structure of excellent mechanical properties.

2. Die Casting:

This process is helpful in the mass production of small and medium parts by injecting molten iron into reusable metal molds, thus ensuring a high-quality surface finish with accurate dimensional tolerances.

3. Sand Molding/Casting:

It is the most versatile type; it uses mold from sand-based materials even to intricate shapes. Variants include green sand, dry sand, and no-bake sand molding, each giving different strengths and finishes.

What are the various properties of gray iron casting?

Gray iron castings possess an extensive property range that renders them of high value in several industrial applications:

a. Graphite Flake Structure:

The peculiar graphite flake microstructure in gray iron casting imparts several important beneficial properties, including excellent vibration damping, high thermal conductivity, and good machinability. The characteristic of grey iron to show a grey fracture is due to the very same graphite flake structure.

b. Mechanical Properties:

Gray iron casting attains high compressive strength, which equals low and medium carbon steels in this aspect. However, its tensile strength and shock resistance are lower and may, therefore, be a limitation in some applications.

c. Thermal Conductivity:

With high thermal conductivity, the characteristic allows such casting to transfer heat effectively, which could be best used in applications like engine blocks and brake components with a demand for heat dissipation.

d. Vibration Damping:

Vibration damping helps reduce noise and wear in bases and housings, particularly on machinery.

e. Easy to Machine:

Being more graphite than metal, these castings are quite machinable and allow for casting into complicated and fragile forms with higher precision.

f. Wear Resistance:

Graphite is present in the material; hence, it has good wear resistance, and this material can be used for components where there are significant forces of friction and wear. These properties make gray iron casting suitable for many applications, including automotive parts, machine bases, and pipe fittings.

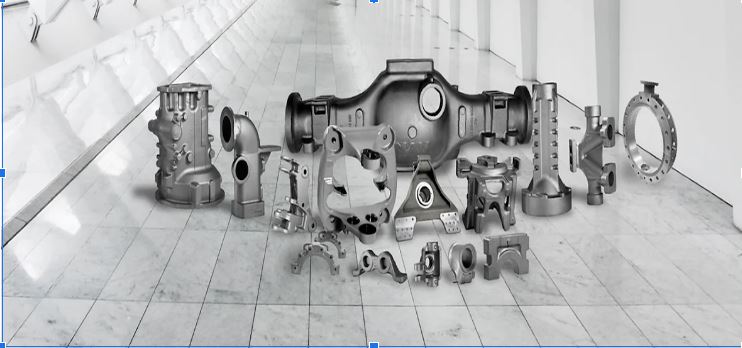

What are the most common uses of gray iron casting?

a. Manhole Covers:

Grey iron is an extremely tough material with a high loading capacity, which is very suitable for use in maintenance hole covers. These covers must withstand heavy traffic with adverse environmental conditions, but they should not bend or break easily.

b. Cinderblocks:

This grey iron cinderblock finds extensive use in the construction field because it is ideal for its strength and stability. They offer an excellent frame for buildings and other kinds of structures, making the whole structure strong.

c. Electrical Boxes:

The excellent machinability of the material lends itself to use in the precise manufacture of electrical boxes, which house wiring and electrical components; hence safety and hardiness are guaranteed.

d. Cylinder Blocks for an Internal Combustion Engine:

Because gray iron has high thermal conductivity, it offers effective heat dissipation by engines. Therefore, its machinability enables the maintenance of complex shapes and acceptable tolerances in engine blocks.

e. Housing of Wind Turbine:

In the housing of wind turbines, the vibration-damping characteristics of gray iron are of utmost importance to help reduce noise and wear because of mechanical vibrations and adverse weather.

f. Gears:

Wear resistance and gray iron’s ability to dampen vibrations make it suitable for manufacturing gears that need to cope with constant motion and friction without degradation in a quick time.

g. Pump Housings:

They benefit from the strength and corrosion resistance of gray iron to assure the end-users that they will be able to rely upon their performance in many fluid handling applications.

h. Hydraulic parts:

Due to the materials’ strength and precision machinability, hydraulic systems will use them as parts that suffer heavily under high pressure and repeated use.

i. Ploughs Shares:

Used in agricultural equipment, gray iron plough shares are known for their durability and wear resistance when working on the tilling of soil used to prepare it for fields.

j. Automotive Suspension Parts:

The suspension parts employ grey iron that can bear heavy loads while it can also absorb the shocks to give a cushioned drive and an edge to vehicle stabilization.

k. Stove Parts:

The high thermal conductivity of grey iron assures uniform heat distribution on stove parts, thus ensuring greater efficiency and consistency in cooking.

l. Valves:

Grey iron valves are solid and durable, resistant to wear and corrosion, and thus used in many industries for assured reliability to ensure guaranteed operation under fluid control systems.

m. Tractor Parts:

Grey iron parts make tractors solid and tough to endure lots of abuse in any agricultural application.

n. Steering Knuckles:

A Critical component in any steering system, the application of grey iron ensures its strength and machinability for better control and durability in steering parts.

o. Machinery Bases:

Due to having excellent vibration-damping features, grey iron is in high demand for machinery bases because it decreases operational noise and extends the lifespan of the equipment. Grey iron’s diverse applications across industries highlight its versatility and the significant advantages it offers in terms of strength, machinability, thermal conductivity, and vibration damping.

Conclusion – Gray iron casting remains a cornerstone in various industries due to its excellent machinability, thermal conductivity, and vibration-damping properties. As a result, gray iron continues to be indispensable in manufacturing, offering a blend of durability, performance, and economic efficiency. AKP Ferrocast, part of AKP Group, excels in high-quality ductile and gray iron casting. The company prides itself on teamwork, quality control, production capacity, and advanced CNC machining.

AKP Ferrocast invests heavily in R&D, collaborating with universities and industry partners to innovate and meet evolving client specifications. Their high standards serve industries like construction, mining, power generation, agriculture, automotive, compressors, and valves. This dedication to continuous improvement and excellence underscores their pivotal role in supporting diverse industrial applications worldwide.

Write and Win: Participate in Creative writing Contest & International Essay Contest and win fabulous prizes.